Ball Valve Parts

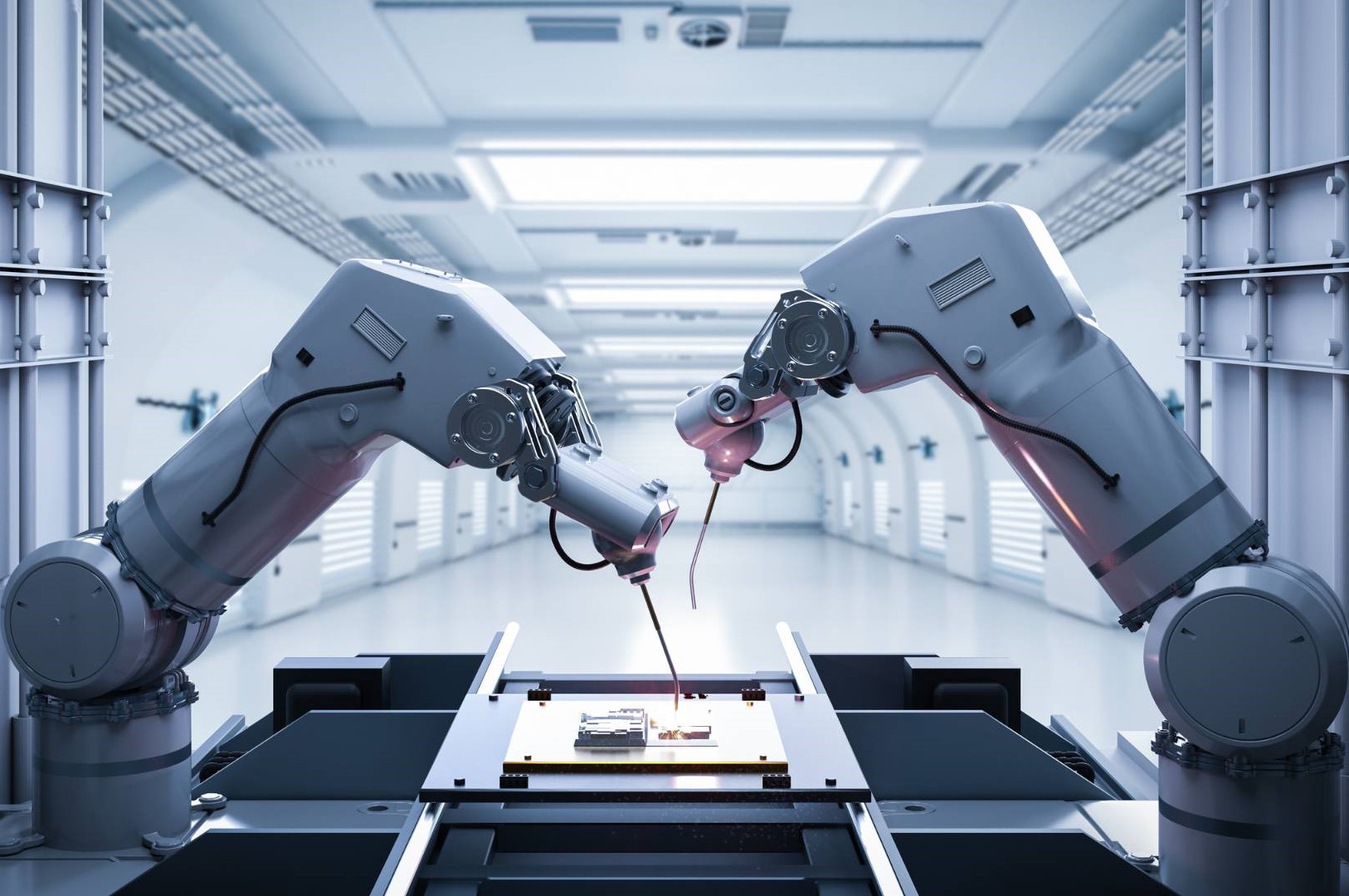

Teknomatic Engineering offers a comprehensive range of high-quality ball valve parts designed to ensure optimal performance and longevity in various industrial applications. Our components are precision-engineered to meet stringent standards, providing reliable solutions for fluid and gas control systems.

Manufactured with precision, our ball valve parts are suitable for applications in oil & gas, chemical processing, water treatment, HVAC, and manufacturing industries. They combine durability, versatility, and ease of installation to deliver reliable performance.

Key Components

- Valve Body: The main housing that contains all internal components and connects to the pipeline system.

- Rotary Ball: The core element that controls the flow of media. It features a central bore that aligns with the pipeline when open and blocks it when closed.

- Seats: Provide a sealing surface between the ball and body. Options include soft seats (PTFE, NBR, EPDM) for low-temperature applications and hard seats (stainless steel, Stellite, tungsten carbide) for abrasive media.

- Stem: Connects the actuator or handle to the ball, transmitting rotational movement. Features include anti-blowout design and low-emission packing for safety and compliance.

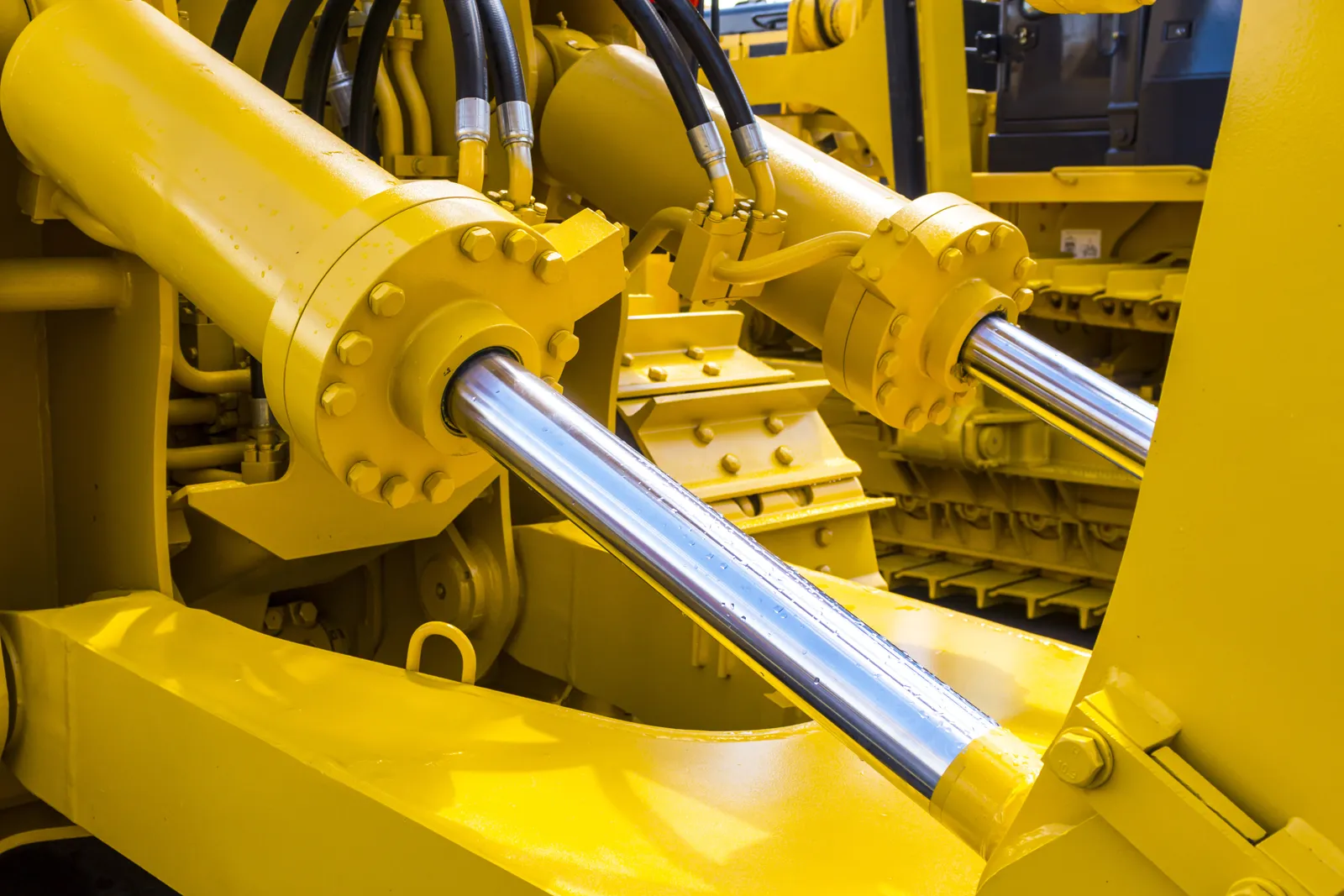

- Actuator: Mechanism that operates the valve. Options include manual handles, pneumatic actuators, electric actuators, and hydraulic actuators, catering to various operational needs.

- Gland Nut and Packing: The gland nut compresses packing material around the stem to prevent leakage. Packing materials include PTFE, graphite, and low-emission designs for hazardous environments.

Specifications & Range

Teknomatic Ball Valve Parts are available in various sizes, materials, and configurations to suit different applications. Below is a representative specification table:

| Component | Material | Size Range | Pressure Rating | Temperature Range |

|---|---|---|---|---|

| Valve Body | Carbon Steel, Stainless Steel, Special Alloys | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

| Rotary Ball | Stainless Steel, Ceramic, PTFE-Coated | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

| Seats | PTFE, NBR, EPDM, Stainless Steel, Stellite | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

| Stem | Stainless Steel, Alloy 625 | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

| Actuator | Aluminum, Stainless Steel | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

| Gland Nut and Packing | PTFE, Graphite | 1/2" to 12" | Up to 10,000 psi | -20°F to 1000°F |

Why Choose Teknomatic Ball Valve Parts?

Teknomatic Ball Valve Parts offer several advantages over traditional valve components:

- Enhanced Durability: Manufactured from high-quality materials to withstand harsh operating conditions.

- Leak-Proof Performance: Precision-engineered components ensure tight seals and prevent leakage.

- Wide Application Range: Suitable for various industries including oil & gas, chemical processing, water treatment, HVAC, and manufacturing.

- Custom Solutions: Components can be tailored to meet specific requirements, including size, material, and pressure rating.

- Compliance with Standards: Manufactured to meet international standards, ensuring consistent quality and performance.