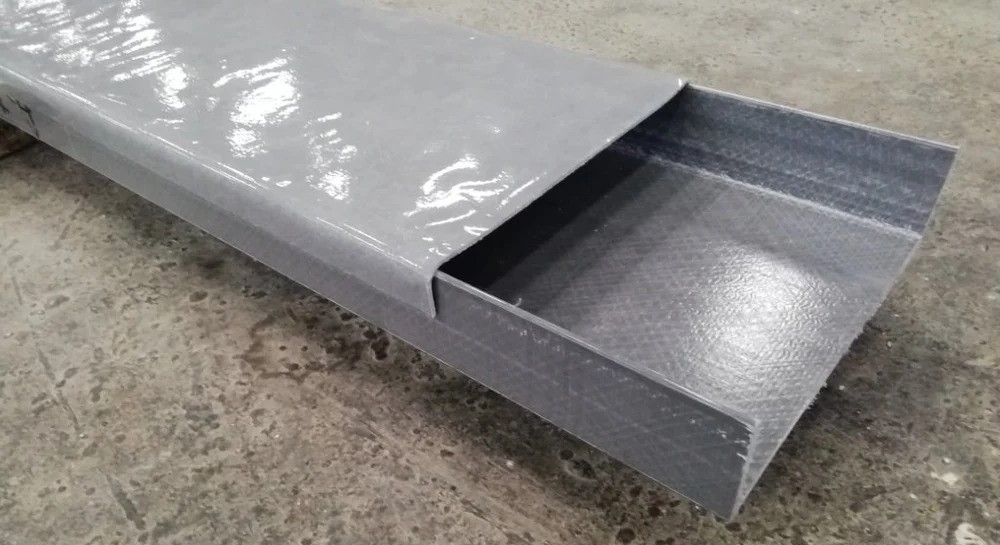

FRP Cable Tray

Teknomatic Engineering offers premium FRP (Fiber Reinforced Polymer) Cable Trays , engineered for safe, durable cable support in corrosive, wet, or electrically sensitive environments. Our trays are ideal for chemical plants, water treatment, offshore, and industrial infrastructure.

These non-metallic trays deliver exceptional performance—lightweight, corrosion-resistant, electrically insulating, and fire-resistant—to ensure long life and low maintenance under demanding conditions.

Key Features & Benefits

- Corrosion & Chemical Resistance: Withstands acids, alkalis, salt spray and moisture.

- Lightweight yet Strong: Up to ~ 40 % lighter than steel trays yet capable of high load support.

- Non-Conductive & Non-Magnetic: Provides electrical insulation and avoids electromagnetic interference.

- Fire / UV Stability: Self-extinguishing options and UV-stabilized resins for outdoor use.

- Dimensional Stability: Minimal shrinkage, warping, or swelling over time.

- Low Maintenance: No rusting, no repainting—trays require minimal upkeep.

- Versatile Configurations: Ladder, perforated, solid bottom, trough types, with covers & accessories.

Specifications & Range

Below is a typical specification range for FRP Cable Trays. Actual values depend on project loading, span, and resin system.

| Specification | Typical Range / Value | Remarks |

|---|---|---|

| Tray Widths | 50 mm to 600 mm | Common widths cover small to large cable bundles. |

| Tray Depth / Height | 50 mm to ~200 mm | Deeper trays suit heavier cable loads. |

| Panel Lengths | 3 m, 6 m or custom lengths | Can be tailored to site layout. |

| Wall / Profile Thickness | 2.5 mm to 5 mm (or higher for heavy duty) | Matched to span and load requirements. |

| Resin Types | Polyester, Vinylester, sometimes Phenolic | Choice affects chemical, fire and UV performance. |

| Standard Fittings / Accessories | Elbows, tees, reducers, covers, splice plates, brackets | Complete modular system for routing & protection. |

Why Choose Our FRP Cable Tray?

Teknomatic FRP Cable Trays deliver a durable, safe, and cost-efficient alternative to metal trays, especially in aggressive or demanding environments.

- Long Life Cycle: Resists corrosion, reducing replacement frequency.

- Safety Assurance: Non-conductive, fire-rated options, minimal hazard risks.

- Ease of Installation: Lightweight, modular design, fewer supports needed.

- Versatility: Wide range of tray types, sizes and customizable options.

- Reduced Maintenance Costs: Negligible upkeep compared to steel trays.

- Quality Control: Manufactured under strict standards and tested for performance.